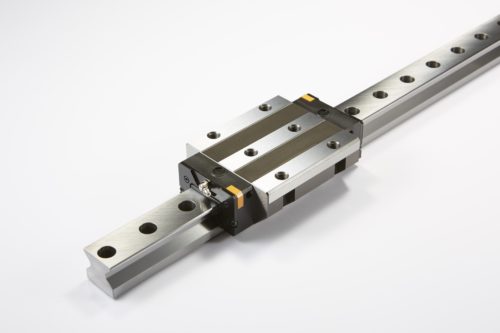

The NB SLIDE GUIDE SGL type is a profile linear guide rail system utilizing the recirculating motion of ball elements along four rows of raceway grooves. It can be used in various applications due to its compactness and high load capacity.

Product Description

At NB, you’ll find linear guide rails and linear guide bearings that cover a wide range of general machinery and high-precision equipment across all industries. Our NB Slide Guide SGL system uses a profile-style rail that takes advantage of the recirculating ball design. It will provide reliable linear movement and positioning for all of your equipment.

By marrying compact design with high-quality materials and precision manufacturing, we can provide high load capabilities for use in small equipment. We’ve included advanced features such as error absorption, dust prevention and integrated lubrication to increase your efficiency and keep your machines running — even in demanding environments.

Advanced Engineering

Industry demands more precise, smaller, lighter and longer-life linear guides and linear bearings. We responded by adding more features and advantages to our NB Slide Guide SGL system. By incorporating our system into your machinery, you benefit from:

High capacity

Large ball elements and tight raceway groove machining provide the greatest contact area possible, which results in higher load ratings, even in single rail applications.

Omnidirectional load

A 45° contact angle (equal top to bottom and side to side) distributes your load evenly and allows for maximum design flexibility and motion.

Low Friction

Thanks to our two-point contact across four rows, our bearings provide low friction and motion that is stable and smooth, even at high speeds.

Installation error reduction

Our self-aligning ball elements absorb dimensional error during mounting. This means faster installation and greater confidence at startup.

Our linear guideways and block assemblies are suitable for general machinery uses as well as high-precision/tight tolerance measurement and optical equipment. Thanks to our high load carrying capacity, it is often possible to design your system to use a single linear guide rail, reducing cost and space requirements.

Adapted to Hard Conditions and Long Use

Your efficiency depends on your equipment being operational and reliable at all times. NB incorporates materials and features that provide longer service life and degradation in demanding environments. Choose NB Slide Guide SGL linear guide rails for all of your applications. You’ll appreciate that we:

• Integrate fiber-sheet lubrication unit into the block to keep your raceway grooves properly lubricated and extend the service life significantly.

• Provide innovative reverse seals that extend the service life even longer.

• Provide dust prevention through multiple seals bellows, scrapers and caps, depending on your needs.

• Increase corrosion resistance with stainless-steel and block or carbon steel with low temperature black chrome treatment (LB).

NB linear guides offer easy and flexible integration into all of your equipment and machinery. To facilitate your design phase, you can download 2D and 3D CAD files and incorporate them into your new machine designs or older machine upgrades. You’ll find an NB Slide Guide SGL system is the perfect solution to your most demanding linear motion problems. Download the CAD files today or contact us for more information.

Structure and Advantages

The NB SLIDE GUIDE SGL type consists of a rail with 4 rows of precisely machined raceway grooves and a block assembly. The block assembly consists of the main body, ball elements, retainers, and return caps.

High Load Capacity and Long Life

The use of relatively large ball elements and raceway grooves machined to a radius close to that of the ball elements increases the contact area resulting in a high load capacity and a long travel life.

Dust Prevention

Side-seals are provided as a standard. To improve the dust prevention characteristics, under-seals, double-seals, scrapers, bellows and special rail mounting caps are also available.

Low Friction

Because a 4-row/2-point contact design is used, low friction and stable motion characteristics are achieved even under a preloaded conditions.

Fiber Sheet Extends

Lubricant Replenishment Intervals

A lubricant-containing Fiber Sheet incorporated in the block supplies appropriate amount of lubricant to the raceway grooves at appropriate intervals, which can significantly extend the lubricant replenishment interval.

Omni-Directional Load Capacity

The ball elements are positioned at 45° contact angle so that the load capacity is equal in four directions (above, below, right and left).

Absorption of Mounting Dimensional Error

Because the ball elements are positioned to increase their self-aligning characteristics, the dimensional error caused during installation is absorbed.

Anti-corrosion Specification

The rail and block assembly can be treated with low temperature black chrome treatment to increase the corrosion resistance. This treatment is standardized with the symbol “LB”. Stainless steel SGLS type is suitable for use in clean room application.

REVERSE-SEAL

NB Reverse-seal realizes maintenance free by reducing grease leakage and loss.

Structure of SGL type SLIDE GUIDE

Types

Nine SGL block types are available depending on the material and mounting method.