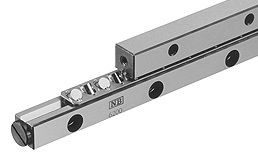

The NB SLIDE WAY is a non-recirculating crossed roller slide way utilizing precision rollers. It is used primarily in optical and measurement equipment where high precision movement is required.

Product Description

NB SLIDE WAY cross roller guides use precision rollers to provide stable, non-recirculating linear motions in equipment such as optical and measuring equipment. NB SLIDE WAY cross roller bearings are suitable for both high-speed and low-speed applications. You can count on them to provide minute motions with exceptional stability and low noise. A perfect solution for medical slide guide needs.

Anti Cage Creep Cross Roller Guide Presentation Video

Please play the video to watch NB’s Innovative Anti-Cage Creep STUDROLLER® System.

Benefits and Features At-a-Glance

At the heart of all NB cross roller bearings is the STUDROLLER® mechanism. The STUDROLLER® system eliminates the cage-creep phenomenon that, over time, can create deviances in cross roller retainer performance. Benefits of this innovative system include:

- Anti cage-creep mechanism

- An up to 58-percent increase in the length of contact between roller and transfer surfaces

- Quieter operation and smoother movement compared to ball circulation guide systems

- Up to 53-percent increase in the number of effective rollers, resulting in load ratings up to 2.3 times higher than conventional sliding bearings

- More accurate linear movements and better performance with minute motions

- Less disparity between static and dynamic frictional resistances

- More stable motion at both high and low speeds

We engineered NB cross roller guides equipped with the STUDROLLER® system from the ground up to be more accurate and better performing than any other product on the market today. Like all of our products, you’ll find NB crossed roller sliding bearing systems being used in some of the most demanding applications and sophisticated equipment in a wide range of industries.

Configurations

Three main configurations of SLIDE WAY sliding bearings are available:

- NV – type sliding plate bearings feature four rails, eight retainers and two end pieces. A retainer (resin or stainless steel) and built-in STUDROLLER® system keep bearings in place, while a track base provides smooth movement and creep-free operation, which facilitates use in multiple positions and with highly accelerated motions.

- SV – type roller bearings feature similar design and functionality to NV products, but with R-type roller cages arranged in a cross formation, minimizing friction resistance. They are available in both resin/steel and all-stainless steel constructions, for use in clean room or corrosive environments.

- SVW – linear roller bearings use a W-type rail to provide a more compact design, while still offering many of the benefits of SV and NV cross rollers. Both stainless steel/resin (SVW) and all-stainless steel (SVWS) configurations are available.

To view a complete list of product specifications, tolerances and dimensions, please contact the NB office today.

Handling Instructions

NB crossed roller bearings are precisely engineered systems that must be handled with care. Do not drop or dent them, and ensure mounting and installation instructions are followed at all times. Cross roller bearing components are designed to be used as a set. Do not attempt to exceed specified load, preload and stroke length ratings.

For more detailed handling instructions, please download the free product catalog.

Structure and Advantages

The NB SLIDE WAY NV type comprises precisely ground rails and R-retainers with built-in innovative anti-creep cage STUDROLLER system and precision crossed rollers. The rails have been optimally designed so that the STUDROLLERs move smoothly, and the STUDROLLERs and precision rollers incorporated in the R-retainers enable cage creep-free operation between the raceway surface and the rollers resulting in motion with minimal frictional resistance. SV and SVW types consist of precision ground rails and precision caged-rollers. Since caged-rollers do not recirculate, there is only a minimum frictional resistance fluctuation. Also, there is a minimal disparity between the static and dynamic frictional resistances.

Suitable for Micro Stroke Operation

As frictional resistance is extremely small and the difference between the static and dynamic frictional resistances are minimal, the NB SLIDE WAY is well suited for micro stroke operation, resulting in highly accurate linear movement.

Low-Speed Stability

Since the frictional resistance fluctuation is small even under low-load conditions, stable motion is obtained at from low to high speeds.

High Rigidity and High Load Capacity

Compared to the ball elements, the rollers provide a larger contact area and less elastic deformation, thus the NB SLIDE WAY has high rigidity and high load capacity. With new NV rail design, the roller contact area is increased by 30 to 58%. The number of effective rollers is increased by narrowing the roller pitch. Thus, the NV type has the load rating that is 1.3 to 2.5 times that of the SV type.

Low Noise

Due to the use of a roller cage, the SLIDE WAY never produces recirculation noise or roller contact noise, resulting in quiet motion.

All Stainless Steel Type Available

The anti-corrosion NVS-RNS/SVS/SVWS SLIDE WAYs have all stainless steel components, making them ideal for clean room and vacuum applications.

※ Fastening plates are attached to the NV type for the purpose of maintaining the center position of the R-retainer before assembly.

STUDROLLER System (Rivet Roller Structure)

The STUDROLLER system is developed based on a new concept to provide complete prevention of roller cage slippage during operation. This system permits to perform in all orientations and positions.

STUDROLLER System

The NV SLIDE WAY consists of a set of four rails, two R-retainers, and eight end pieces. It permits flexible design of the table which will best suit your application. Now available in all stainless steel components for high temperature conditions such as vacuum and anti-corrosive environments.

The NV SLIDE WAY consists of a set of four rails, two R-retainers, and eight end pieces. It permits flexible design of the table which will best suit your application. Now available in all stainless steel components for high temperature conditions such as vacuum and anti-corrosive environments.

The SV SLIDE WAY consists of a set of four rails, two R type roller cages, which have precision rollers in a cross arrangement, and eight end pieces. The all stainless steel option makes it suitable for use in corrosive environments.

The SV SLIDE WAY consists of a set of four rails, two R type roller cages, which have precision rollers in a cross arrangement, and eight end pieces. The all stainless steel option makes it suitable for use in corrosive environments.

The SVW SLIDE WAY consists of two SV-type rails, one W type rail, two R type roller cages, and eight end pieces. The use of a W-type rail serves for a compact design. The SVWS type is also available with all stainless steel components

The SVW SLIDE WAY consists of two SV-type rails, one W type rail, two R type roller cages, and eight end pieces. The use of a W-type rail serves for a compact design. The SVWS type is also available with all stainless steel components