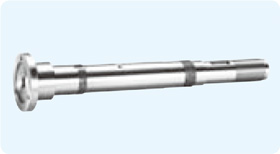

The NB Linear Shaft can be used in a wide range of applications as a mechanical component as straight shaft.

Linear Shafts

Product Description

NB’s engineering expertise encompasses a wide range of manufacturing and machining capabilities for linear shafting, bearing rails and other equipment components. With sophisticated machinery, industry-leading quality control processes and a history of innovation dating back to 1939, we can meet your requirements for accuracy, toughness and precision.

Keep browsing our website to learn more about our rotational and linear bearing rail manufacturing capabilities or contact our office by phone or email to discuss your requirements with one of our engineers.

Benefits and Features At-a-Glance

NB has invested in advanced machining technology — including CNC lathes, cylindrical grinding machines, boring and milling machines, and more — to meet any client’s engineering requirements. We can perform everything from tapping, shaft-stepping and linear bearing rail manufacturing. As a result, we can design products that offer:

Superior damage resistance

Using advanced heat treatment technology, we can improve the resistance of our rotational and linear shafting devices. Our quenching and tempering processes create a uniformly hardened outer layer that resists damage commonly incurred over time.

Decreased surface roughness

A smooth surface is essential to improving the performance and accuracy of our products. NB linear bearing rails are precision-grinded to ensure roughness is limited to no more than Ra0.4.

For a complete list of engineering specifications, angle calculations and other information, download our linear shafting product catalog or contact an NB representative directly.

Wide Range of Options

You can find NB shafts and linear bearing rails in a diverse range of applications, including manufacturing equipment, consumer goods and more. To customize products to the specific needs of our clients, we offer many manufacturing options, including:

- Various coatings, including chroming and ceramics, as well as repair and resurfacing services for older components

- A range of different materials, including high-carbon chromium bearing steel and Martensitic stainless steel

- Multiple product types, including NB SFW/SFWS/SN/SNS/SNT components and other high-precision shafts for our own slide bushings and bearings

We also can manufacture SNB/SNSB center-lined tapped shafts and SFW-PD/SFWS-PD pre-drilled inch shafts for NB shaft support rails. Using NB linear bearing rails can save time in the design and assembly processes as well as simplify installation. Contact a representative to discuss whether or not this is an option for your project.

Committed to Precision and Accuracy

We complete all machining and fabrication services in our state of the art facility. This ensures we adhere to the highest standards of quality control and can effortlessly scale our processes up to fulfill high-volume orders. Qualified technicians who have access to sophisticated measuring tools test all products to confirm they meet your requirements for dimensional tolerance.

Count on NB for all of your precision machining needs, including manufacturing of linear bearing rails and rotational shafts. Call or email our office to request a quote today.

Structure and Advantages

NB’s expertise in machining and heat-treatment turns into manufacturing spindle shaft, roll shaft, and general machinery shaft for rotational motion. NB’s high accuracy technology answers various shaft machining requirements.

Advanced Machining Technology

NB performs a wide variety of highly accurate machining processes to provide the custom shafting from relatively simple machining, such as tapping and shaft stepping, to the highspeed rotating shafts and spindles. NB can also answer the special grinding and bore machining requirements.

Special Requirements

Based on the customer drawings and specifications NB will answer the customer requirements in material (SCM, SKS etc.), heat-treatment, surface treatment, etc.

Excellent Wear Resistance

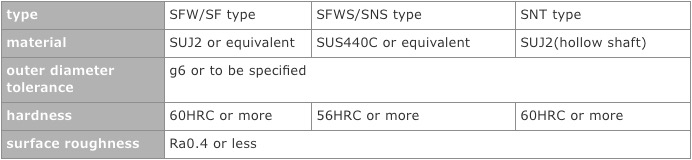

Most commonly used materials are high-carbon chromium bearing steel (SUJ2 or equivalent) and martensite stainless steel (SUS440C or equivalent). NB’s advanced heat-treatment technology gives these materials an excellent wear resistance by quenching and tempering to achieve a uniform hardened layer in the circumferential and axial directions. The cross-sectional picture below shows the hardened layer-depth of the NB shaft.

Shaft Supporter and Shaft Support Rail

These components ease the shaft installation and help save the design/assembling time.

Surface Roughness

Precision grinding results in a surface roughness of less than Ra 0.4

FIT Series

FIT series is a set of a linear bushing and a linear shafting. By precise shaft-grinding, FIT series achieves the best-fit clearance adjustment for a smooth, high accuracy linear motion.

Wide Selection of Shaft Types

SF type, SNS type, SNT type, SNB, SNSB type (Center-lined tapped shaft) SFW, SFWS type (Inch shaft) SFW-PD, SFWS-PD type (Inch, pre-drilled shaft) Spindle shaft, roll shaft

SFW/SFWS type (Inch Series)

SF/SNS/SNT type (Metric Series)

NB Linear Shaft is a high-precision shaft that can be used with slide bush or any other bearings. A wide range of machining is provided for customer drawings and requirements.

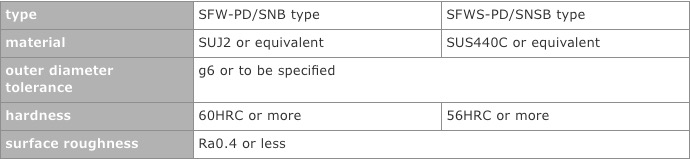

SFW-PD/SFWS-PD type (Inch Series Center-lined Pre-Drilled Shaft)

SNB/SNSB type(Metric Series Center-lined Pre-Drilled Shaft)

Center-lined pre-drilled tapped shafts are standardized series for easy selection that can be used with the SA shaft support rails.

The SFW and SFWS types are inch dimensional shafts with the same specifications as SF/SNS type. SFW-PD and SFWS-PD types are standardized series that can be used with the WA shaft support rails.

Shaft Supporter and Shaft Support Rail

WH-A/WA/LWA type (Inch Series)

SH-A/SH/SHF, SHF-FC/SA type (Metric Series)

Special Specifications

Based on drawings and specifications NB manufactures spindle shafts, roll shafts that are for the rotary motion. Material, heat-treatment (hardening/tempering), surface treatment, etc. NB meets customer requirements. Please contact NB for details.